Researchers: M.Sc. Muhammad Wasim Tahir; Prof. Dr.-Ing. habil. Clemens Merten

Complete thermal model of a lithium-ion battery consists of two parts: 1) electrochemical heat generation model and 2) heat transfer model. A detailed multi-scale multi-domain (MSMD) thermal model for two different types of high-power lithium-ion batteries has been developed. 1D electrochemical model developed at the Institute of Technical Thermodynamics (ITT), German Aerospace Center (DLR) has been made to interact with a 3D finite element (FE) heat transfer model. A coupling strategy has been devised to make interaction between electrochemical and thermal models more efficient and dynamic preserving much of the geometrical details and electrochemical complexities.

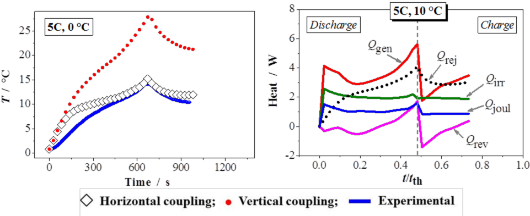

Figure 1: Left: Simulated cell surface temperature obtained through horizontal and vertical coupling along with measured cell surface temperature as a function of time at 5C and 0 °C ambient temperature; and Right: Overall heat generation (Qgen) along with individual contributions like reversible (Qrev), irreversible (Qirr), joule (Qjoul) as well as overall heat dissipation (Qrej) at 5C and 10 °C ambient temperatures for a single discharge/charge cycle. Qrej is the sum of heat dissipated due to convection and to radiation (PhD work of M. Wasim Tahir).

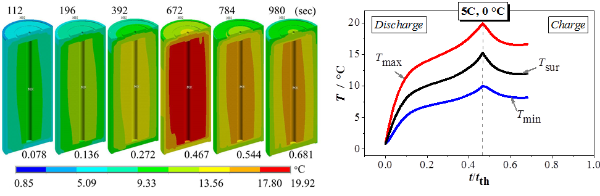

Figure 2: Left: Temperature contours on bisection of a high-power lithium-ion cell obtained at different times during the simulation of discharge/charge cycle at 5C current and 0 °C ambient temperature. On bottom is the normalized time (t/tth) which is the ratio of actual simulation time to theoretical time while at the top is actual simulation time in seconds. Right: Line plots of maximum (Tmax), minimum (Tmin), and surface (Tsur) temperatures of the cell for 5C current and 0 °C ambient temperature (PhD work of M. Wasim Tahir).

Two coupling strategies i.e. 1) vertical coupling and 2) horizontal coupling have been tried. Model has been validated against measured data and found to be in good agreement. The MSMD model can be used as an adequate tool for design and optimization of thermal management systems of EV battery packs and modules. Pulse power response of the cells has also been investigated through detailed simulations.

Animation: FreedomCAR’s [1] hybrid pulse power characterization (HPPC) test has been simulated on a 2.3 Ah high-power lithium-ion cell. 20C discharge (acceleration) and 15C charge (regeneration) pulses have been applied each for 10 seconds separated by a 40 seconds relaxation phase at -10 °C [263 K] ambient temperature and 50 % start SOC (state of charge). Animation shows the resulted temperature variations on bisection of the cell. Absolute temperature [K] scale and time in seconds have been used in the animation.

- [1] FreedomCAR Battery Test Manual for Power-Assist Hybrid Electric Vehicles, Idaho National Engineering & Environmental Laboratory, Idaho, U.S.A., 2003.